wire edm machine is an electro process

Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. Wire Electrical Discharge Machine.

What Is Wire Edm Electrical Discharge Machining Xact

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece.

. The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task. The theory on which Electrical Discharge Machining EDM is based is centuries old. This method remove materials by using a controlled and fast frequent electrical charges.

The experiment was executed on the CNC WIRE CUT EDM MACHINE MODEL EX7732 at the Wire-EDM lab at MNNIT Allahabad Prayagraj India as shown in Fig. What is Wire EDM. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive.

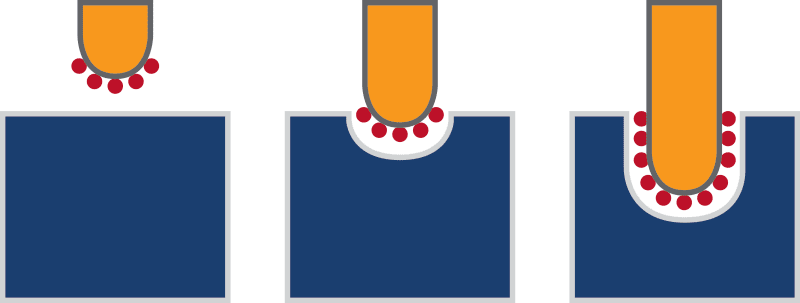

It cuts using the same mechanism as die-sinking. In this process a metal workpiece that is to be machined is clamped into machining bed. A specially designed tool emits sparks in terms of thousands cut the material.

EDM is a process of cutting where the cutter is either an electrode or a wire. The titanium alloy-Grade 5 Ti-6Al-4 V which is employed extensively on account of its high corrosion resistance high strength to weight ratio and biocompatibility. It is not the most popular CNC machining process available.

However the die is replaced with a very fine electrically charged wire which will work as the electrode. The process is applicable only for electrical conductive materials such as metals. Also the cutting tool applies the force to remove the material from the work-piece during machining.

The nature of the Wire EDM process means that you can achieve shapes and structures that are next to impossible with other CNC methods and can give you incredible results. This material must be conductive and electrically grounded to complete the electrical circuit. EDM stands for E lectrical D ischarge M achining.

The Electrical Discharge Machining EDM is an unconventional. The sinker EDM also referred to as ram EDM is the most commonly used EDM type today. EDM stands for Electrical Discharge Machining.

It can be plastic metals for any material that may result in a. Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust. Wire EDM in process Wire EDM machine.

The electrodes used in sinker EDM are pre-machined to form a reverse or mirror image of the workpiece. The term EDM stands for Electrical Discharge Machining. Usually they are non-ferrous and include steel titanium.

It is a precision process of creating high voltage sparks to vaporize metal. A metallic wire usually brass or copper has high voltage electrical discharges passed through it that allows it to cut through the entire thickness of the material. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust.

The Wire-electro discharge machining process generates a much higher temperature at the wire-work piece interface which can potentially change the. The Electro Erosion process is often used in the production of blanking and casting dies. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always harder than the work-piece.

Ad Tailor-Made For The Latest Generation Of EDMs With Variable Pressure. Wire EDM otherwise known as wire erosion is commonly used to produce extrusion dies. EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal conductive part.

Sinker Electrical Discharge Machine. Wire EDM can precisely machine the most complex parts out of hard conductive materials such as pre. However engineers rely on it to create parts that are impossible to machine.

Up to 10 cash back To increase the productivity and quality of the machined components wire electro-discharge machine parameters such as cutting speed kerf width and surface roughness are often optimized. Wire EDM is a type of CNC machining technology capable of unique results. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece.

This process allows the wire to cut through metal by the use of heat from electrical sparks. Hole Electrical DIscharge Machine 1 Sinker Electrical Discharge Machining. Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method.

EDM is similar to processes such as laser cutting. The electrodewire are electrically charged and are held at a high voltage usually in the range of 20 to 50 thousand volts. Electrical Discharge Machining or EDM is a manufacturing operation used for shaping different workpieces into complex parts.

You are unaware of many items that are made out of electrical discharge machining.

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Mas 865 How To Make Something That Makes Almost Anything

Electrical Discharge Machine Sinker Edm And Wire Edm

Wire Edm Find Suppliers Processes Material

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control

Wire Edm Find Suppliers Processes Material

Wire Cut Edm Process 2 Download Scientific Diagram

Schematic Diagram Of A Wire Edm Machine Download Scientific Diagram

Wire Electric Discharge Machining Wire Edm Youtube

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Machining Sprutcam 14 All Lang User Manual

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

What Is Wire Edm Electrical Discharge Machining Xact

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

What Is Wire Edm Electrical Discharge Machining Xact

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Wire Electrical Discharge Machining An Overview Sciencedirect Topics